AUTOCLAVED FIBER CEMENT SLABS LATONIT СН

LATONIT CH AUTOCLAVED FIBER CEMENT SLABS

LATONIT CH fiber cement slab is an absolutely innovative product which is currently UNPARALLELED on the Russian market. Like other LATONIT products, it is a multipurpose and environmentally friendly product.

LATONIT compressed fiber cement slabs are a composite material made fr om reinforcing fibers, mineral fillers and binding material. Cement ensures the product strength and moisture resistance. Mineral fillers add certain inherent plasticity to the fiber cement slabs. Fibers enhance stiffness of the slabs, reduce linear expansion under the temperature impact and serve as internal reinforcement of the material.

Autoclaving process is a hydrothermal treatment of fiber cement slabs with saturated steam at high temperature and pressure. This process facilitates homogeneous structure of fiber cement to ensure high resistance of LATONIT CH slabs to aggressive environment or mechanical damage. Calcium hydroxide Са(ОН)2 (cement hydration product) reacts with silicon oxide SiO2 in the autoclave. The presence of water medium and high temperature causes silica dissolution on the sand grain surfaces wh ere the resultant solution then reacts with the calcium hydroxide essence that results in the generation of calcium silicate hydrate. At first they are jelly-like, then they gradually crystallize and transform into solid crystals with splicing sand grains together. Due to this process, LATONIT CH slab is a sort of integral block which is absolutely not susceptible to chemical changes under heat and water exposure, and is resistant to mineral salt solutions. Lime precipitation (efflorescence) takes place on the treated boards.

The autoclaving process allows to reduce fiber cement shrinkage that is the root cause of product cracking both during board curing and operation.

LATONIT CH autoclaved painted fiber cement slabs have a low linear expansion coefficient during operation under any higher and lower temperature conditions. This property reduces spontaneous cracking and peeling of the painted surface from the slab and thus increases the painted surface life!

LATONIT CH fiber cement slabs are the products with a high impact strength of at least 3 kgf cm/cm2. The material features an increased strength and is capable to withstand impact loads without failure.

Like the entire LATONIT fiber cement slabs family, LATONIT CH autoclaved slab is a modern, affordable and very easy-to-use material.

Acrylic-dispersion-based painting compounds specifically developed for fibre cement boards are used to paint LATONIT boards. After being applied and polymerized, they form weatherproof, vapor-permeable protective and decorative coating having high wear and temperature-drop resistance. The painting color may be selected from RAL, NSC, RAL Design catalogs or customer’s samples.

Ecology:

- Choice and environmentally friendly raw materials NO heavy metals, NO solvents, NO formaldehydes, No potentially hazardous chemicals

- Conformity to Russian quality standards LATONIT fiber cement boards have passed all the certification tests and have the required certificates of conformity and technical approvals by the Ministry of Construction of the Russian Federation.

- Fire safety Nonflammable and non-fire spreading

- Undemanding to weather conditions Fiber cement boards may be used at -50 °C to +80 °C, with their quality and dimensions always remaining stable regardless of temperature and humidity

- 100 % recyclable material The company assists in recycling of its product at the end of their lifecycle

- Conformity to European quality standards The quality and safety of LATONIT fiber cement boards is supported by a European Union Certificate. That certificate entitles to apply EC mark on the products, which indicates that the manufacturer provides the customers with exceptionally quality and safe products that do not contain or emit noxious substances during processing or operation

- Safety for human health LATONIT fiber cement boards do not contain or emit noxious substances during processing or operation

Dimensions*:

| Length, mm: | 3000 |

| Width, mm: | 1500 |

| Thickness, mm: | 8 |

* Note: Boards of different sizes may be manufactured upon coordination with the customer

Physico-mechanical properties:

-

Ultimate flexural strength, MPa (kgf/cm2), minimum:

23 (230 kg/cm2)

-

Toughness, minimum:

2,5 kJ/m2

-

Weathering resistance (number of cycles): 90

- Protective properties: No coating disbondment or visible defects A31

- Decorative properties: Minor lightening of coating color AD2

After exposure to water and 5 % NaOH solution, 3 % sea salt solution, no color change or coating disbondment should occur. AD1A31

-

Density:

1,8 g/cm3

-

Freeze thaw resistance:

- Number of alternating freezing and thawing cycles: 150

- Residual strength, minimum: 90%

-

Paint and varnish coating resistance to static effect of liquids:

After exposure to 0,5 % H2SO4 solution, minor color lightening is allowed. No coating disbondment or visible defects are allowed. AD2A31

- Nominal light resistance: No change in color or appearance is allowed

- Paint and varnish coating adhesion: 1

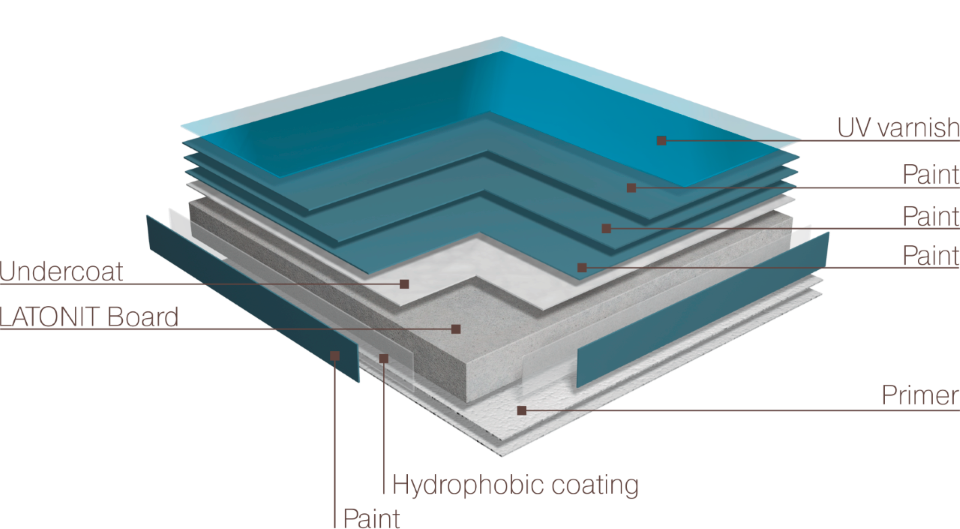

Coating structure

LATONIT fiber cement boards are painted on modern lines in strict accordance with the board preparation and painting process.

After the boards are cut per the customer’s dimensions, their face is ground and saturated with a special mixture to strengthen the fiber cement board’s top layer. Then, the sides are treated and painted. After that, the prepared fiber cement boards arrive at the painting line.

The first step of painting is applying a primer compound on the board’s face. Then, three-coat painting of the board’s face and two-coat painting of board’s rear surface are performed simultaneously. The final step of the painting is UV varnish application. This step increases the strength of the paint-and-varnish coating, extends the painted surface’s life, and improves the surface’s resistance to chemical exposures.

All the paint-and-varnish coating application steps are done under constant control by the quality control department and the laboratory, which ensures high quality of the LATONIT painted fiber cement products.