When working with the boards, do not: pull off, move off, impact, throw from any height, walk on the decorative surface.

Additional cutting of products with protective and decorative coating is performed while the board is placed facing upwards on a specialized sawing table (machine) ensuring geometrical accuracy of the work performance, using special equipment with a dust arrester to avoid fiber cement dust conjunction with airborne moisture, and decorative coating deterioration. Also, the board cut must be cleaned with air (using compressor) or mechanically (soft brush, rags, etc.), followed by treatment of the cut with a hydrophobic material.

The sawing table (machine) shall be placed in a room or under a cover precluding exposure to atmospheric precipitations. Sawing and drilling are only performed with dry boards.

Board sawing tools:

- Portable saws (handsaws) with a dust arrester

- Stationary saw with a dust arrester

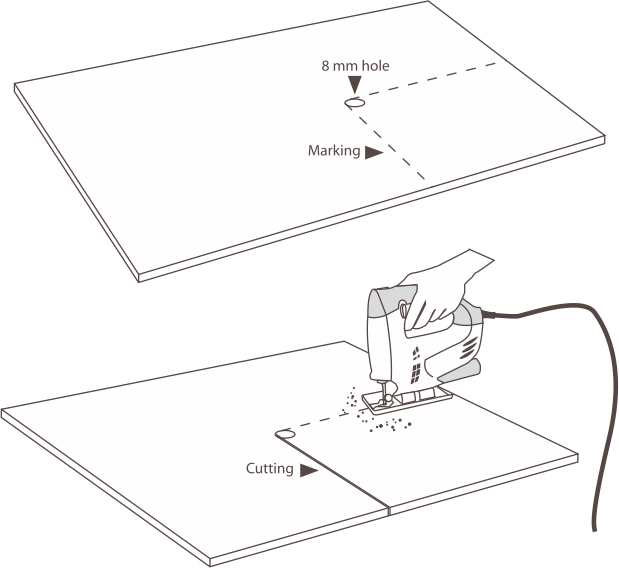

- Scroll saw for small and curved cuts

Special disc for cutting of abrasive materials are used:

- Carbide-soldered

- Silicon carbide disks

- Diamond disks with variable cross section.

The sawing cut shall be even, smooth, without spalls or burrs. For stationary saws, the mounting flange diameter shall be 2/3 of the saw diameter to avoid fatigue fractures. The saw’s butt beat shall be within +0,1 mm.